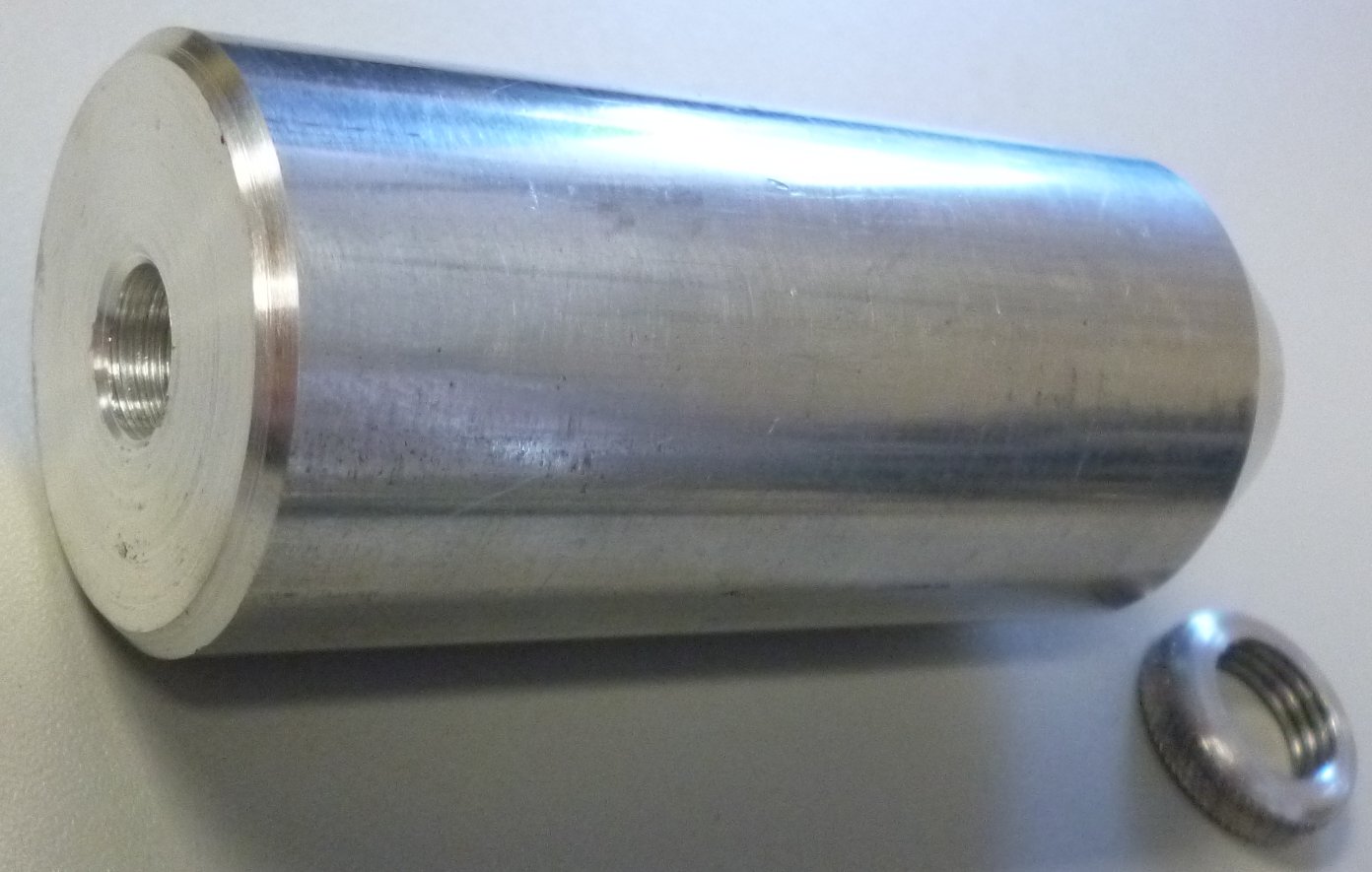

| Bolt Knob Just because I can I decided to make a nice alloy bolt knob. The first thing to do is grind down the existing knob to a nice round shaft shape which can then be threaded. I did this by grinding the knob down on two sides to just larger than the diameter of the bolt arm. I then marked to lines on one flat which gave me a stop line for grinding down the two remaining sides so that I ended up with a slightly oversize square. I then gently rounded this down on the workshop linisher with a nice worn belt. I got this to a size suitable for tapping with a 6mm metric thread. I went ahead and ran a die nut down the shaft, buffed the thread up on the wire wheel then sand blasted the whole part which I will be re-blueing before final reassembly. I also thought I'd play around with some bronze that was lying around and make a "low profile" bolt knob. Muzzle Brake Many would argue that a calibre such as the 7.62x39 doesn't really need the "taming" assistance of a muzzle brake and I would tend to agree...however with easy access to a lathe and milling machine plus a length of 30mm alloy how could I say no. I had a look at what is out there on the market already and took my design cues from them.

|